Rayterton Maintenance Management System (CMMS/EAM)

Rayterton CMMS helps manufacturing plants control asset lifecycles, preventive maintenance, work orders, calibration, and safety compliance in one execution layer. It improves asset uptime and operational safety while keeping cost performance visible through clear operational KPIs.

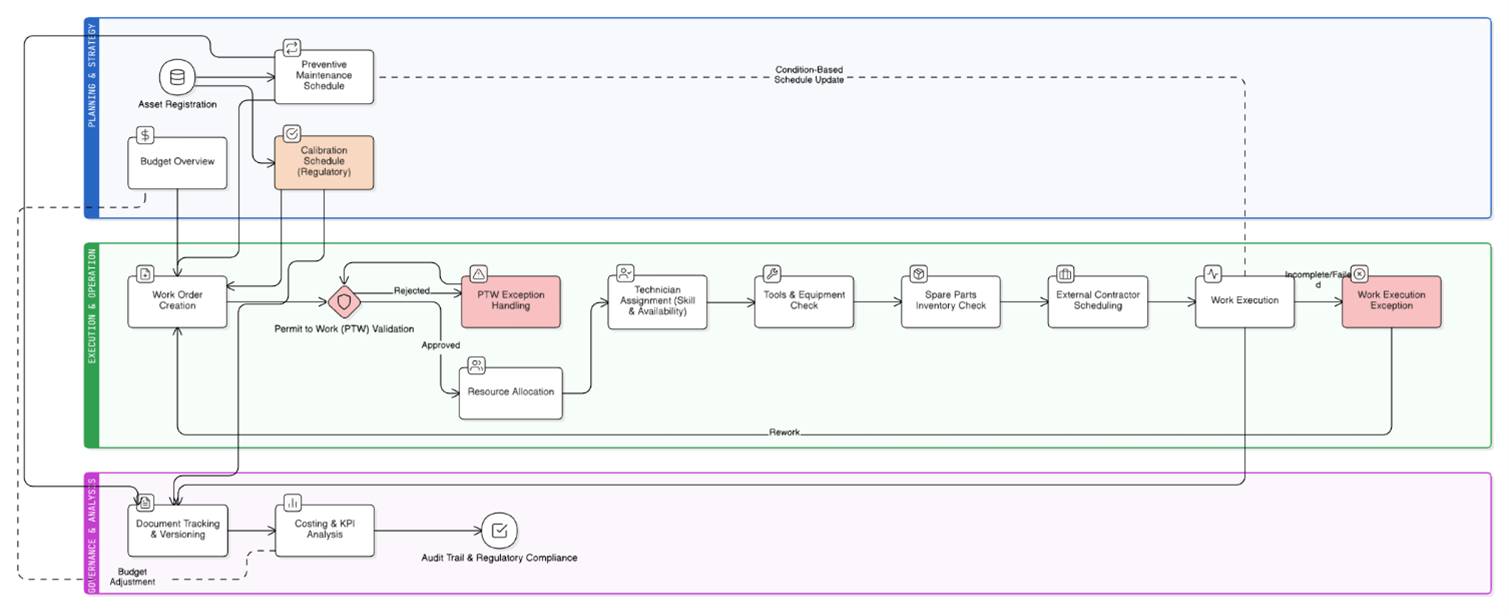

End-to-end operating story

About Rayterton CMMS

Rayterton CMMS is designed for industrial plants that need consistent asset reliability and fast maintenance response. It supports asset registration, preventive scheduling, work order execution, resource allocation, and document control with standard standards such as calibration tracking, safety permits, and audit trails. Maintenance activity is tracked with operational KPIs so teams can monitor costs, backlog, and compliance per site, department, and team.

Executive Maintenance Command Center

This area supports executives and operations leaders who need fast clarity on asset health, maintenance costs, and compliance risk. It answers simple questions: What is broken now? What is due next? What is over budget? What is compliant? It links KPIs to drilldowns so teams can move from insight to action quickly.

Core capabilities:

- Real-time Asset and Operations Control Tower covering uptime status, open work orders, safety permits, critical breakdowns, and resource availability.

- Operational Alerts and SLA Watchlist for equipment downtime, overdue maintenance, failed calibrations, safety incidents, and budget overruns.

- Exception to Action Workflows that route issues directly to the responsible team (planning, execution, calibration, safety, procurement).

- Executive KPI Cockpit for MTBF (Mean Time Between Failures), MTTR (Mean Time To Repair), schedule compliance, maintenance cost per unit, and overall equipment effectiveness (OEE).

Asset Intelligence and Maintenance Planning

Asset reliability must be consistent and controlled. This section treats asset registration, preventive logic, and scheduling as required foundations. Maintenance becomes effective only after it is planned and scheduled correctly. This reduces unexpected downtime, emergency repairs, and operational delays.

Core capabilities:

- Asset Register and Hierarchy to centralize all equipment data, serial numbers, locations, and technical specifications.

- Preventive Maintenance Scheduling to generate automatic maintenance tasks based on time intervals, usage meters, or condition-based triggers.

- Spare Parts Association to link critical spare parts to specific assets for faster retrieval during repairs.

- Maintenance Logic Engine to define specific task lists, safety instructions, and required tools for every preventive job.

Work Order Execution and Resource Control

Execution performance depends on how fast technicians can resolve issues without administrative friction. Work orders follow clear priorities and constraints. Resource allocation ensures the right person does the job. Permits are managed as a safety discipline. The goal is speed that stays safe under pressure, with documentation at scale.

Core capabilities:

- Work Order Creation and Management for corrective, preventive, and emergency tasks with priority levels and clear descriptions.

- Resource Allocation to assign specific technicians or vendors based on availability, skill set, and workload capacity.

- Permit to Work (PTW) Control to integrate safety permits (hot work, height, confined space) directly into the work order flow.

- Execution Tracking to monitor job status, actual hours worked, parts consumed, and completion remarks.

Calibration and Regulatory Compliance

Manufacturing plants need compliance that holds up during strict audits. This area standardizes calibration scheduling through continuous monitoring, result verification, and certificate management. It provides evidence that proves equipment accuracy and safety during external audits.

Core capabilities:

- Calibration Schedule Management to track due dates for all measuring and test equipment.

- Result Verification and Pass/Fail Logic to record calibration readings and automatically flag equipment that falls outside tolerance limits.

- Regulatory Compliance Dashboards to visualize the percentage of compliant assets and identify high-risk areas immediately.

- Certificate Tracking to store and retrieve digital calibration certificates and legal documents linked to specific assets.

Costing, Analytics, and Document Governance

Financial control depends on details. Budget allocation, cost analysis, and document versions all matter. This area makes maintenance costs predictable. Expenses are tracked through controlled stages with audit validation. It supports multiple reporting standards to improve financial decision-making and audit readiness.

Core capabilities:

- Budget Overview and Tracking to set maintenance budgets per department and monitor actual spending against the plan in real-time.

- Costing Analysis to calculate total cost of ownership (TCO) including labor, spare parts, and external vendor services.

- Document Control and Versioning to manage manuals, standard operating procedures (SOPs), and drawings with strict revision history.

- Full Audit Trail to record every user action, approval, and data change for security and regulatory inquiries.

Mobile Operations and Offline Sync

A CMMS must support execution in the field and not just the office. This area adds mobility, offline capability, and remote data capture to the platform. It helps maintenance teams scale coverage while keeping data accurate and timely.

Core capabilities:

- Mobile Work Order Execution allowing technicians to view tasks, update status, and close jobs from their mobile devices.

- Offline Synchronization to ensure data is captured and stored locally when internet access is unavailable, then synced automatically when online.

- Mobile Asset Management to scan QR codes or barcodes on equipment to instantly view history and open requests.

- Evidence Capture to allow technicians to take photos of damage or completed repairs and attach them directly to the work order.

Glossary of terms & abbreviations

- CMMS = Computerized Maintenance Management System. A system to help plants manage asset lifecycles and maintenance.

- EAM = Enterprise Asset Management. A term often paired with CMMS in the context of comprehensive asset management.

- KPI = Key Performance Indicator. A measurable value used to evaluate the success of operations and track performance metrics.

- SLA = Service Level Agreement. A commitment between service providers and clients regarding expected service levels, often monitored via watchlists for accountability.

- MTBF = Mean Time Between Failures. Average time between equipment failures.

- MTTR = Mean Time To Repair. Average time required for repairs.

- OEE = Overall Equipment Effectiveness. Overall effectiveness of equipment.

- PTW = Permit to Work. Safety work permits (such as hot work, height, confined space) integrated into workflows.

- TCO = Total Cost of Ownership. Total ownership cost including labor, spare parts, and external vendor services.

- SOPs = Standard Operating Procedures. Standard operating procedures managed with strict revision history.

- Asset Register = Centralized asset register covering equipment data, serial numbers, locations, and technical specifications.

- Preventive Maintenance = Automatic scheduling of maintenance tasks based on time intervals, usage meters, or condition-based triggers.

- Calibration = Process of verifying results and pass/fail logic for measuring equipment to ensure accuracy and regulatory compliance.

- Work Order = Work command for corrective, preventive, or emergency repair tasks.

- Audit Trail = Complete record of every user action, approval, and data change for security and regulatory inspection purposes.

- QR Codes = Quick response codes used in mobile asset management to scan and instantly view equipment history.

Ready to fully customize Maintenance Management System to your needs

Share your structure, policies, and pain points. Rayterton will deliver Maintenance Management System customized to your processes, enabling consistent maintenance workflows, accurate asset data, while addressing your main concerns.